In a groundbreaking accomplishment, astronauts aboard the International Space Station (ISS) have achieved an impressive 98% water recovery rate, thanks to a remarkable advancement in recycling technology designed to handle an unconventional source: astronaut urine. This significant milestone is set to revolutionize low-orbit space missions by providing astronauts with essential resources such as food, air, and water without relying on resupply missions.

Water is a vital resource for the ISS crew, with each member requiring approximately one gallon per day for drinking, food preparation, and hygiene purposes. The ultimate goal has been to achieve a 98% recovery rate of the water initially brought into space, enabling longer missions to be self-sustaining.

Christopher Brown, a member of the team at Johnson Space Center responsible for managing life support systems on the ISS, expressed the importance of this achievement, stating, “This is a very important step forward in the evolution of life support systems. Keeping that running is a pretty awesome achievement.”

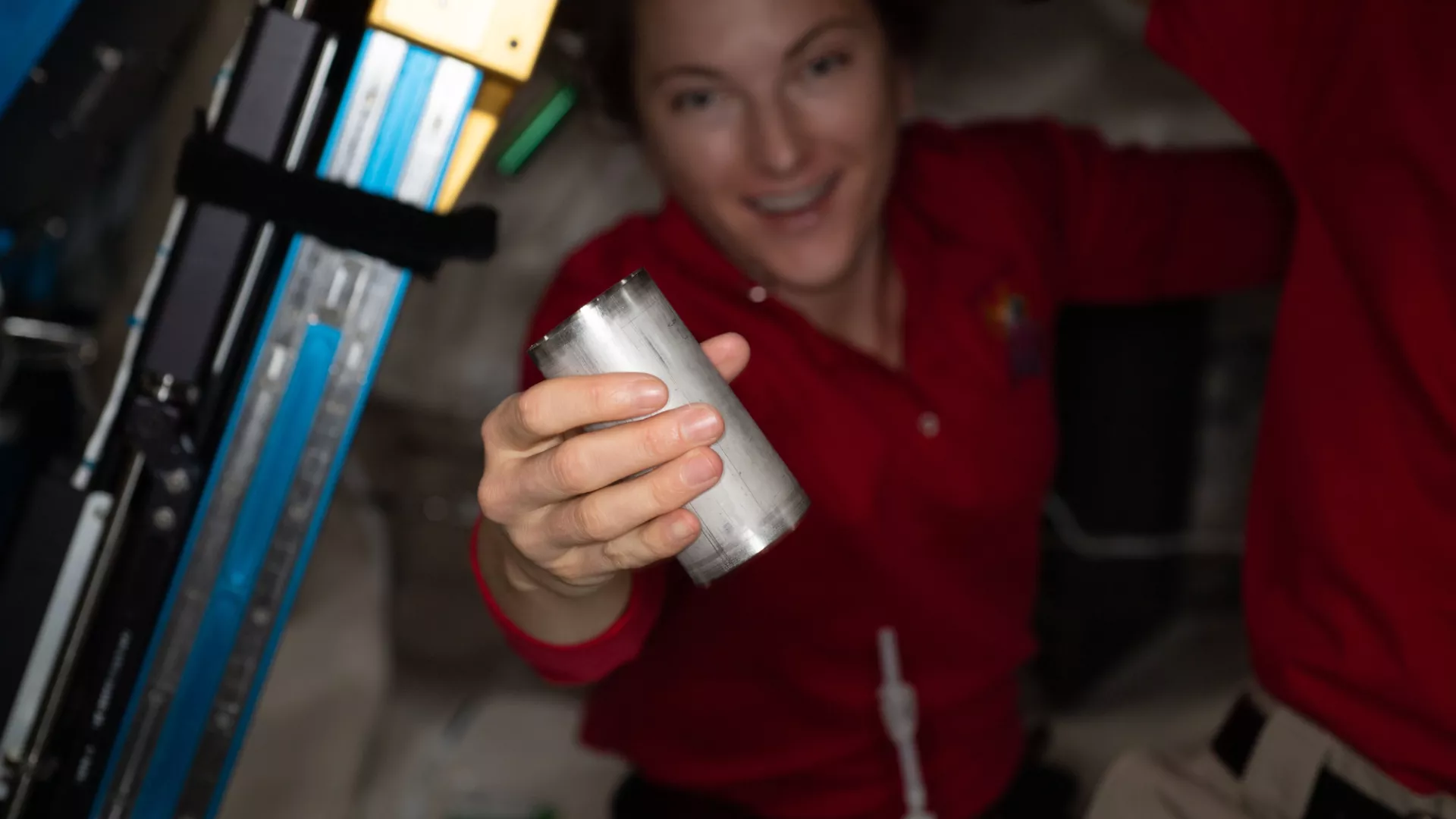

The key to this water recovery milestone lies in the improved Urine Processor Assembly (UPA) of the Environmental Control and Life Support System (ECLSS). The UPA employs vacuum distillation to extract water from urine, resulting in the production of brine as a by-product. To maximize water recovery, a Brine Processor Assembly (BPA) was integrated with the UPA, extracting the remaining wastewater and pushing the ECLSS to the 98% target.

The BPA employs special membranes to introduce brine to warm dry air, facilitating the evaporation of its water content. The resulting humid air, similar to the breath of ISS crew members, is then collected by ECLSS dehumidifiers. The collected wastewater, including the humid air, undergoes treatment by the Water Processor Assembly (WPA), which utilizes specialized filters and a catalytic reactor to remove any remaining contaminants. Water purity is meticulously monitored, with any water failing to meet standards is sent back for reprocessing. Finally, iodine is added to the acceptable water to prevent microbial growth, ensuring its safety for the crew’s consumption.

It is important to note that the water produced on the ISS is not derived from urine, but rather from the reclaimed, filtered, and cleaned water that surpasses the quality of municipal water systems on Earth. Jill Williamson, ECLSS water subsystems manager, clarifies, “The crew is not drinking urine; they are drinking water that has been reclaimed, filtered, and cleaned such that it is cleaner than what we drink here on Earth.”

To ensure the reliability and longevity of the ECLSS systems, extensive testing is conducted to verify their performance and demonstrate their ability to function with minimal maintenance or replacement parts.

This achievement is a significant stride forward for future space missions, particularly as astronauts embark on longer stays on the lunar surface and crewed missions to Mars. The regenerative ECLSS systems will play a pivotal role in these endeavours, enabling the crew to reclaim all the necessary resources without relying on resupply missions. This not only reduces the need to transport water and oxygen but also allows for more scientific equipment to be included in the launch vehicle.

Jill Williamson concludes, “Reliable, robust regenerative systems mean the crew doesn’t have to worry about it and can focus on the true intent of their mission.”

With the astronauts aboard the ISS demonstrating their ability to achieve such an exceptional water recovery rate, the future of sustainable space exploration appears brighter than ever before.